A printed circuit board

- Categories:Electronic product

- Author:

- Origin:

- Time of issue:2022-05-20

- Views:0

(Summary description)Printed circuit board labels

Printed circuit board identification and traceability

Labels on printed circuit boards are subjected to tremendous stress during their production process. Poor quality or damaged prints can have an impact on production process monitoring, logistics and the use of printed circuit boards in the final product.

These requirements for message clarity and durability are at the heart of the printing solution selection process.

printed circuit board label printing

The techniques used for part welding and residue cleaning are very demanding: for example, temperatures can reach as high as 300°C (572°F), and the dispersion of solvents under high pressure can easily destroy labels and printed messages.

Laboratory weathering tests in some areas with harsh environmental conditions (such as aviation, automotive and armament) reproduce the large mechanical and thermal stresses (UV resistance, humidity, heat, cold, temperature changes, etc.) to which printed labels will be subjected.

Certain international printing performance regulations (UL standards) and regulations covering the use of regulated substances also necessarily form part of the process of selecting a printing technology.

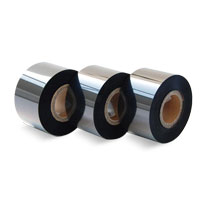

CISON's printed circuit board label printing ribbon

Thermal transfer technology is the most reliable printing technology for printing uniform information on printed circuit board labels.

The high fidelity of the printhead produces fairly accurate prints of all types of barcodes (vertical, horizontal, data matrix, 2D, etc.), alphanumeric characters and logos, even on very small labels.

CISON's resin inks combined with synthetic labels (polyester, nylon, polypropylene or polyimide) provide the best solution in terms of print quality and resistance to high temperatures, abrasion and solvents.

A printed circuit board

(Summary description)Printed circuit board labels

Printed circuit board identification and traceability

Labels on printed circuit boards are subjected to tremendous stress during their production process. Poor quality or damaged prints can have an impact on production process monitoring, logistics and the use of printed circuit boards in the final product.

These requirements for message clarity and durability are at the heart of the printing solution selection process.

printed circuit board label printing

The techniques used for part welding and residue cleaning are very demanding: for example, temperatures can reach as high as 300°C (572°F), and the dispersion of solvents under high pressure can easily destroy labels and printed messages.

Laboratory weathering tests in some areas with harsh environmental conditions (such as aviation, automotive and armament) reproduce the large mechanical and thermal stresses (UV resistance, humidity, heat, cold, temperature changes, etc.) to which printed labels will be subjected.

Certain international printing performance regulations (UL standards) and regulations covering the use of regulated substances also necessarily form part of the process of selecting a printing technology.

CISON's printed circuit board label printing ribbon

Thermal transfer technology is the most reliable printing technology for printing uniform information on printed circuit board labels.

The high fidelity of the printhead produces fairly accurate prints of all types of barcodes (vertical, horizontal, data matrix, 2D, etc.), alphanumeric characters and logos, even on very small labels.

CISON's resin inks combined with synthetic labels (polyester, nylon, polypropylene or polyimide) provide the best solution in terms of print quality and resistance to high temperatures, abrasion and solvents.

- Categories:Electronic product

- Author:

- Origin:

- Time of issue:2022-05-20

- Views:0

Printed circuit board labels

Printed circuit board identification and traceability

Labels on printed circuit boards are subjected to tremendous stress during their production process. Poor quality or damaged prints can have an impact on production process monitoring, logistics and the use of printed circuit boards in the final product.

These requirements for message clarity and durability are at the heart of the printing solution selection process.

printed circuit board label printing

The techniques used for part welding and residue cleaning are very demanding: for example, temperatures can reach as high as 300°C (572°F), and the dispersion of solvents under high pressure can easily destroy labels and printed messages.

Laboratory weathering tests in some areas with harsh environmental conditions (such as aviation, automotive and armament) reproduce the large mechanical and thermal stresses (UV resistance, humidity, heat, cold, temperature changes, etc.) to which printed labels will be subjected.

Certain international printing performance regulations (UL standards) and regulations covering the use of regulated substances also necessarily form part of the process of selecting a printing technology.

CISON's printed circuit board label printing ribbon

Thermal transfer technology is the most reliable printing technology for printing uniform information on printed circuit board labels.

The high fidelity of the printhead produces fairly accurate prints of all types of barcodes (vertical, horizontal, data matrix, 2D, etc.), alphanumeric characters and logos, even on very small labels.

CISON's resin inks combined with synthetic labels (polyester, nylon, polypropylene or polyimide) provide the best solution in terms of print quality and resistance to high temperatures, abrasion and solvents.

Scan the QR code to read on your phone

Shantou high tech zone jusheng technology Co.Ltd

Tel: 86 754 88461930

Wechat official account : KRUBO-CISON

Add:15/F,WeiGao Building,NO.2,Keji East Road,GaoXin Zone, Shantou City, Guangdong Province

Copyright © Shantou high tech zone jusheng technology Co.Ltd. All Rights Reserved 粤ICP备05059720号 Powered by:www.300.cn SEO tags

Wechat official account